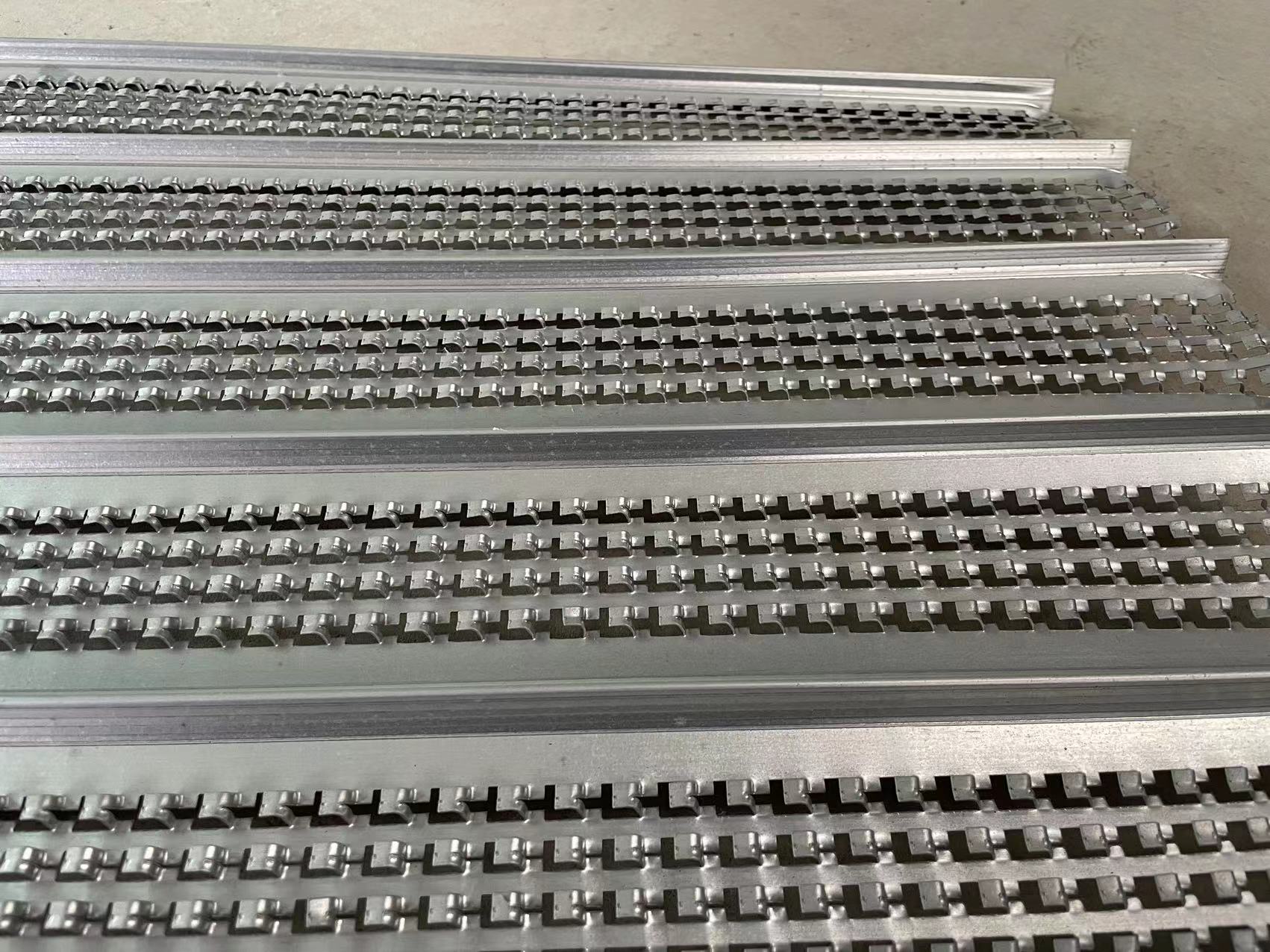

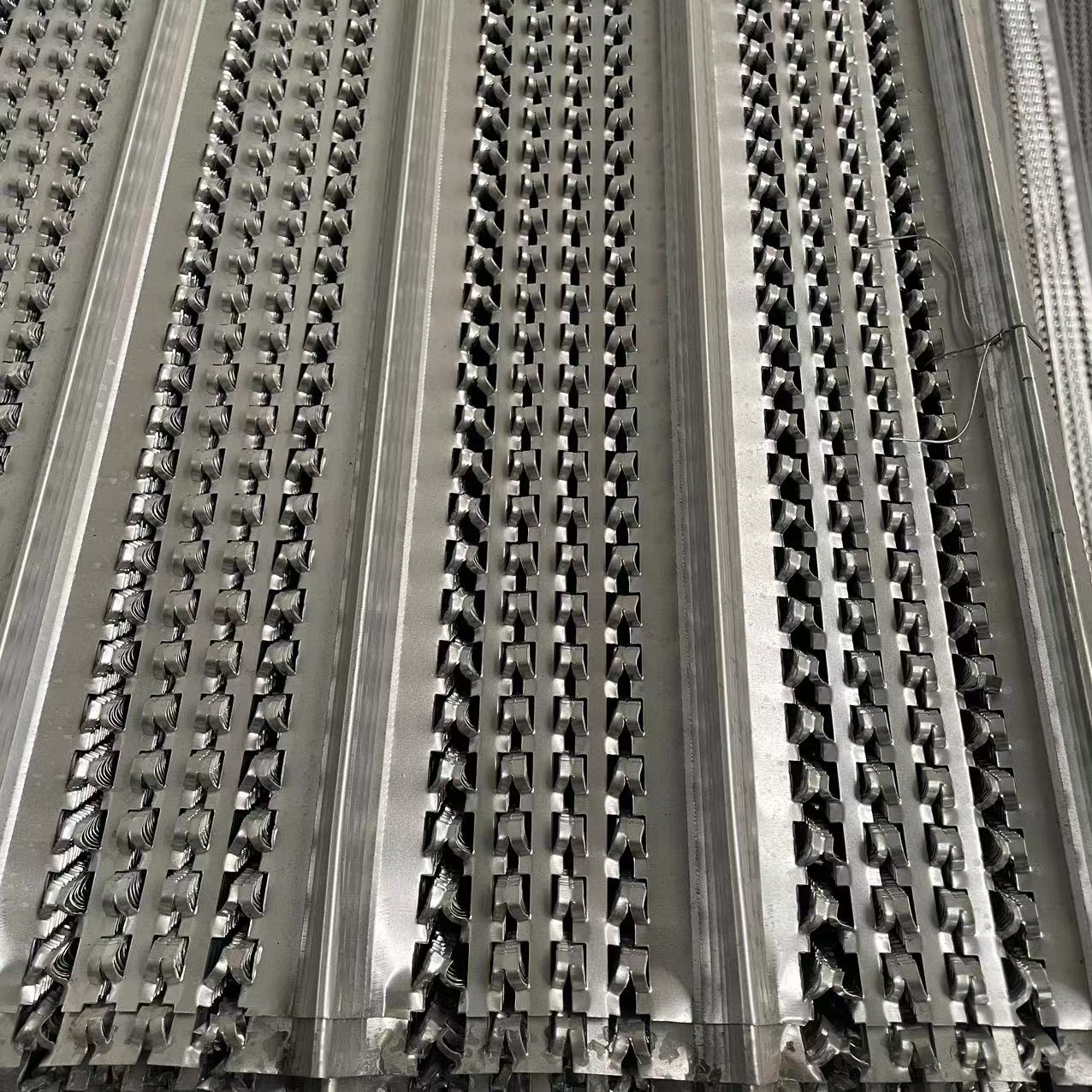

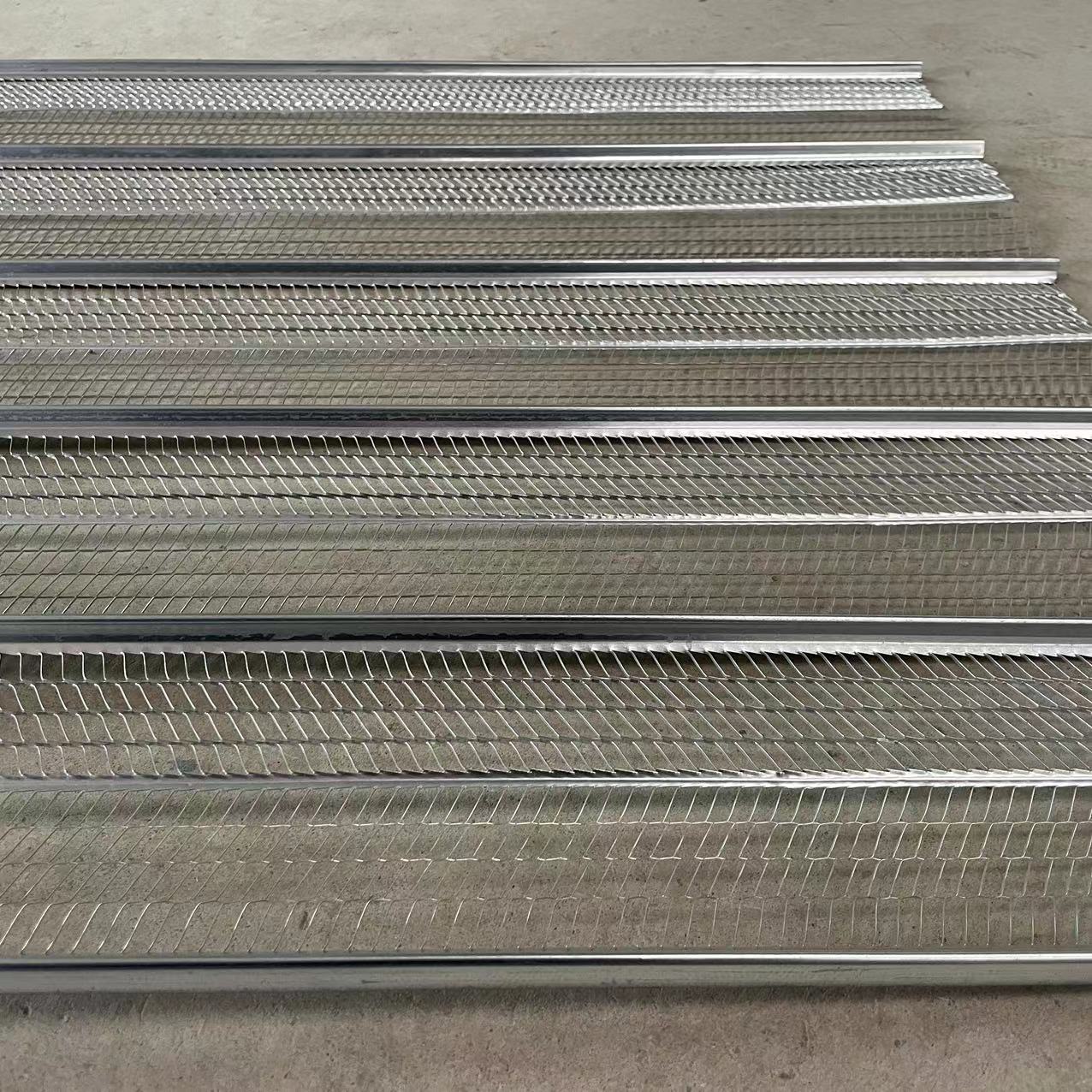

Due to the porosity of the closing mesh, a dense special mesh is used, and steel bars of less than 12mm can be used to pass through it with a little force. Steel bars with a slightly larger diameter can be cut through the grid, and the plate can be returned to its position after the steel bars pass through. The quick-and-easy closing net can also be installed before tying the steel bars, and then can be inserted through its mesh to install it.

Direct observation of the pouring process

Due to its special mesh, the pouring process can be monitored with the naked eye, thereby reducing the risk of pores and honeycombs.

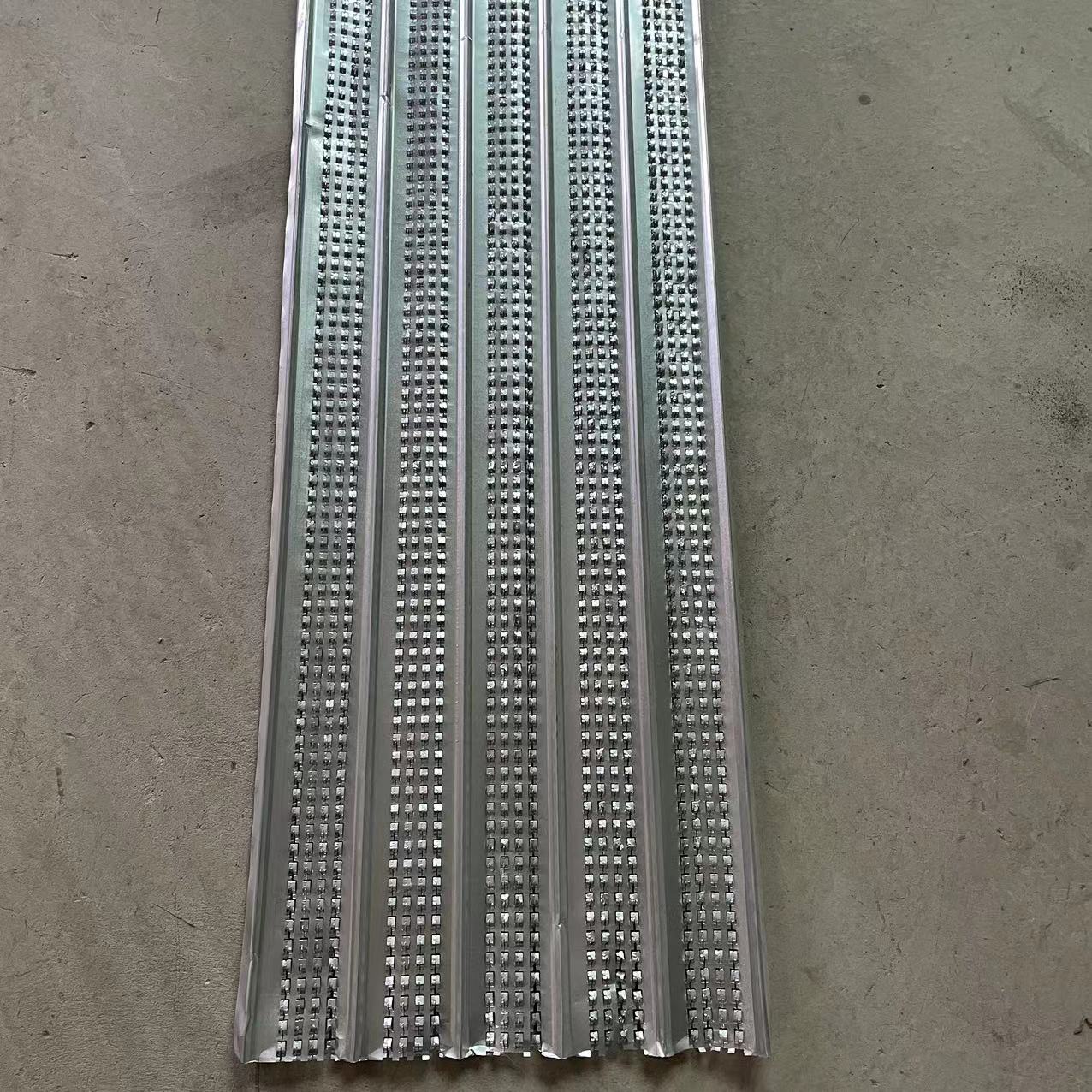

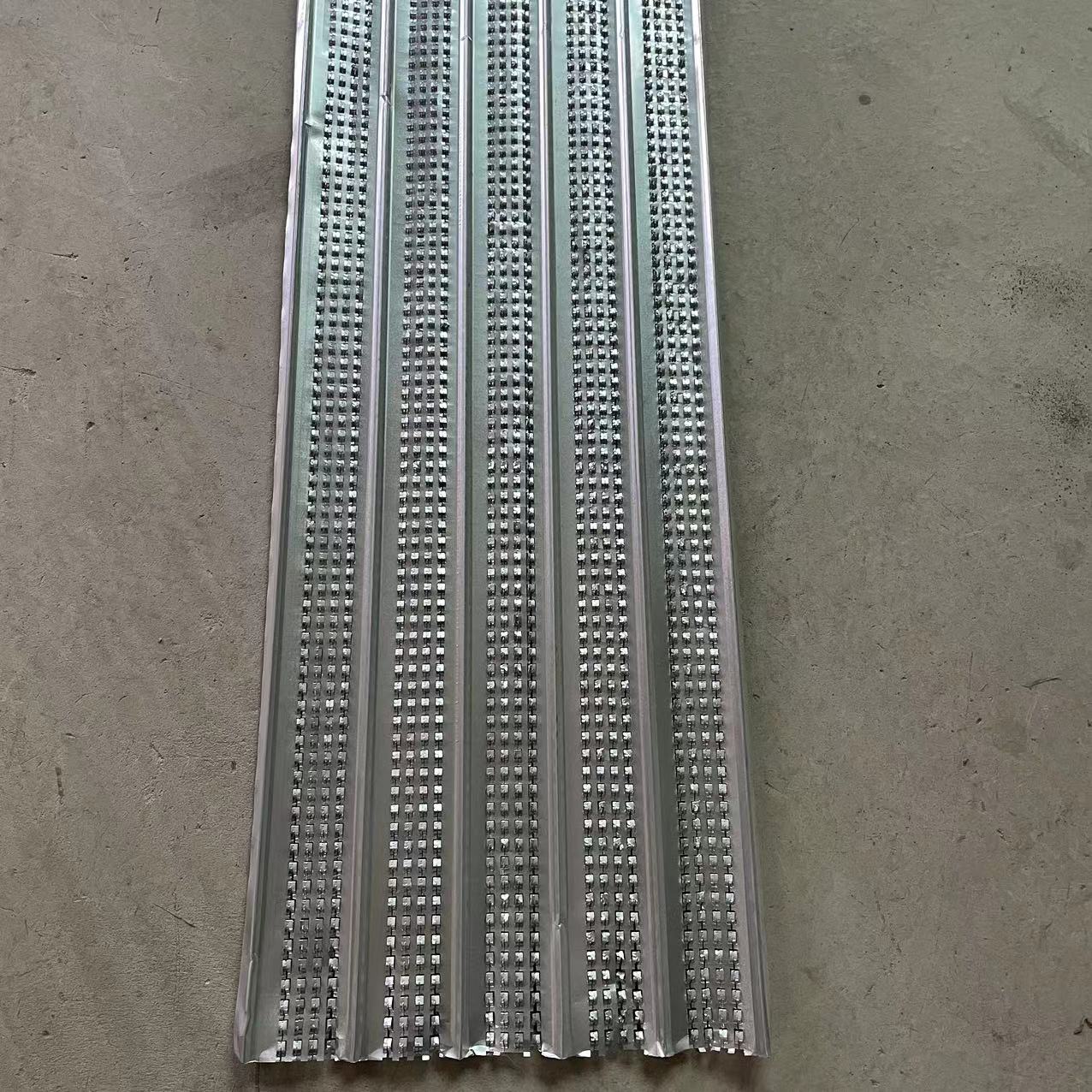

Light weight, easy to transport and install

It is only one-tenth the weight of ordinary shaped steel molds, is quick to install and easy to transport.

Optimize the process and increase the shear-resistant interface

During pouring, the mortar penetrates into the interface through the mesh holes to form a coarse-grained interface with ideal shear resistance.

Adapt to staged concrete pouring, construction is civilized

The permanent formwork can be bonded to the next pour of concrete without removing the formwork or preparing joints, thus simplifying the joint preparation work.

Easy to install and cut

Multifunctional, easy to cut, and can be bent and formed according to the required mold shape.

Good mechanical properties and small side pressure

Disassembly-free formwork is a permanent formwork combined with concrete. After the concrete is poured, the angular fitting of the hole mesh will be automatically embedded. This creates a mechanical key for the next poured concrete, which has strong adhesion and shear resistance to the joint quality. After the concrete is poured, there is no need to dismantle it, just remove the bracket, saving time and labor and speeding up the construction progress.

In extreme climate (hot or cold) environments, the quick and easy closing mesh will not peel or deform. The quick and easy closing net is uniquely designed to retain the poured concrete. It is easy to monitor the pouring of concrete during construction and can reduce the risk of voids, honeycombs and sand holes.

A rough surface is formed at the interface, providing an ideal joint surface for the next continuous pouring. There is no need for manual chiseling, roughening, cleaning, maintenance, etc. before the second pouring operation can be carried out, so that the new and old concrete can be combined into a strong bond. Overall, leakproof. At the same time, it also avoids structural damage caused by the vibration of chiseling and roughening. The mesh holes can help disperse the water pressure generated by the cement mortar during pouring, reducing the concrete pouring pressure by up to 2/3, which is lower than the lateral pressure of traditional formwork. Much less, which can save a lot of template brackets and reduce labor and material costs. Leaving the surface on the surface after pouring concrete can serve as a reinforcement to prevent dry shrinkage of the concrete surface and humidity shrinkage cracks.